DIAMOND DRESSING TOOLS

Providing You With Quality Diamond Dressing Tools

New Jersey Diamond Products Co., Inc. in Paterson, NJ manufactures a variety of diamond tools used for industrial purposes.

We Manufacture

Single pointed diamond tools are used on various grinding machines to dress the surface of an abrasive wheel. The size and quality of the diamond can vary according to wheel size, required finishes and finished part tolerances. Shank sizes and shapes will change depending on machine requirements.

Cluster diamond tools have many of the same properties as single point diamond tools, except they have multiple diamonds set in the head. Cluster tools can also be set in multiple layers to allow for extended use.

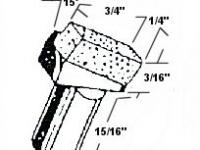

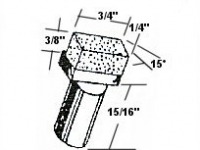

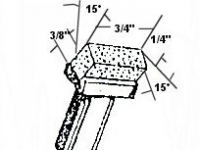

Impregnated Tools

Impregnated diamond tools, also called grit tools, are made with diamond powder or grit, formed with metal matrix into a block and mounted on a specified type shank. This type of tool is used when heavier dressing is required. The different shank and block configurations allow the operator many choices for his particular machine and application.

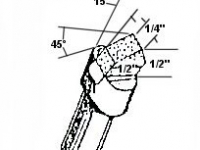

Cones and phono points are made from round elongated natural diamonds of only the finest quality. They are used to dress fine thin wheels that need to be accurately trued into irregular shapes. Standard cones and phono points are made by grinding an included angle of between 60 to 120 degrees on the diamond that is mounted in a straight shank. They can also be made to customer specifications with other angles and unlimited shank configurations.

Chisel edge dressers and other shape tools are usually made from flat elongated high quality diamonds .The lapped edge of this type of tool usually has a radius. As with Cones, standard Chisels are made with included angles of 60 to 120 degrees having a straight shank. There are many popular shape tools that are standard in the industry. Many of these tools can be relapped if the operator avoids overuse.